Tuesday, October 17, 2017

Standard Railgate Maintenance - Tips & Procedures

Best practices and maintenance procedures for Standard Railgate models.

—

When it comes to liftgates for straight trucks, Railgate models are among the most popular. And, since Railgate lifts come in a wide variety of styles and sizes, keeping up to date on basic maintenance procedures is crucial to ensuring that any Railgate is always functioning as intended. Being aware of and following a few, good-liftgate-ownership practices will also reduce the need for liftgate repairs in the future.

NOTE: It is important to keep in mind that some Railgate models require more care and attention than others. High-Cycle Railgates, for example, due to their roller-based drive system, do not call for as frequent service and/or inspection as say Standard or Dock-Friendly Railgate models. So, for the purposes of this article, the focus will be primarily on the Standard (& Dock-Friendly) variety.

1. Oil the Outrails (The #1 Standard Railgate Owner's Tip)

For Standard Railgate models, the first (and arguably most important) practice to follow closely is to properly lubricate the outrails. Outrails are the vertical tracks which mount to the back of the vehicle body and guide the sliders up and down during lifting action. On all Standard Railgate models it is imperative that the outrails are correctly lubricated and clear of debris. When the outrails are dry or not lubricated properly the sliders may get hung up, or “shimmy,” and cause the platform to unlevel.

The outrail on a Tommy Gate Standard Railgate.

When lubricating the outrails on Standard Railgate models, be sure to always use a clean, high-quality, nondetergent, petroleum-based oil - DO NOT USE GREASE. Use nondetergent 10W@(14°F-32°F), 20W@(32°F-104°F), and 30W@(104°F-122°F).

NOTE: DO NOT USE GREASE. The application of grease in the outrails may cause clogging due to the accumulation of road grit and debris.

2. Oil the Roller Chains

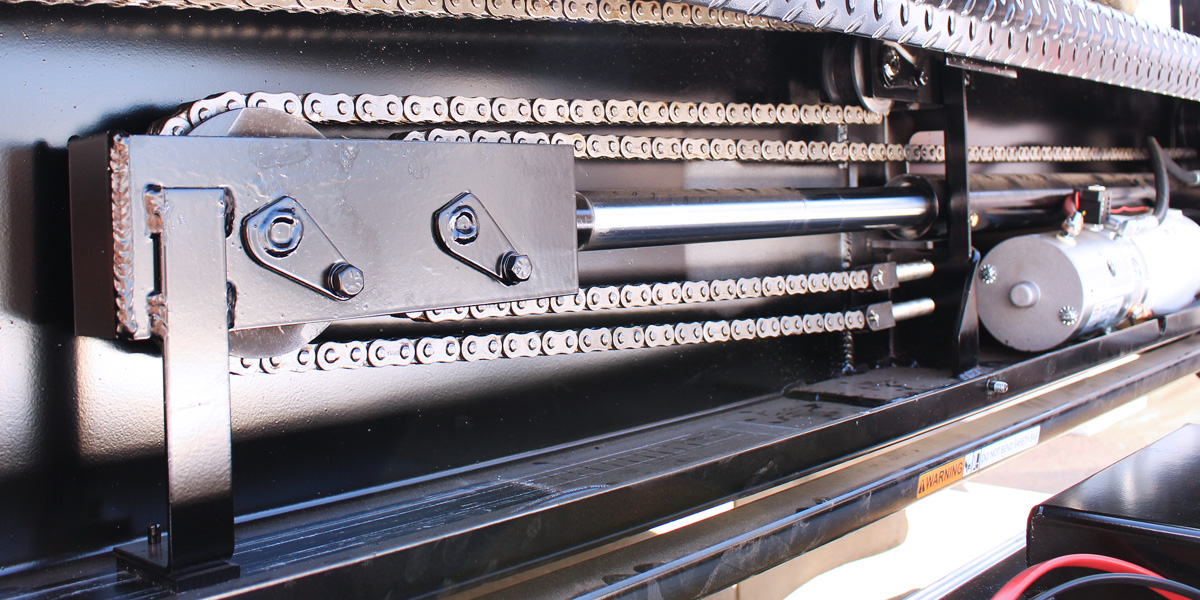

In order for the liftgate to operate properly, it is also necessary to keep the roller chain lubricated. Much like on a bicycle, a well-oiled liftgate chain is vital for all moving parts to run smoothly. The chain on a Standard Railgate lift can be accessed via the open space in the outrails or by removing the liftgate box cover. Again, use only a clean, high-quality, nondetergent, petroleum-based oil.

Exposed Cylinder and interior roller chain on a Standard Railgate.

3. Loading the Platform

Paying close attention to how the platform is loaded is another key to maximizing the efficiency and longevity of a Standard Railgate lift.

Loads should be placed near the center of the platform in order to equally distribute the lifting effort to both sides of the lift. For heavier loads, center and place as close to the rear of the vehicle as possible. Proper placement of cargo on a railgate platform can help to eliminate the possibility of unlevel movement and the need for future repairs.

___________________________________________________________

Basic Maintenance Information

Tommy Gate Railgate models are recommended for service every 120 days or 1500 cycles, whichever comes first.

IMPORTANT: The liftgate will not be automatically serviced when the vehicle is serviced.

If there is any noticeable problem with the liftgate between service intervals, the liftgate must be taken out of service and checked immediately.

All installations, re-installations, and repairs of Tommy Gate Railgates should be performed by a qualified, authorized distributor that is familiar with its operation and safety features. All replacement parts must be of original quality, and all safety and operational decals must be attached. No modifications are allowed to be made to a Tommy Gate product unless authorized by the Tommy Gate Engineering Department.

Tommy Gate Pump & Motor Reservoir with hoses and fittings.

Maintenance Procedures

- Remove the box cover.

- Check for fluid leaks from the cylinder, hoses, and all fittings (replace and repair if found to be leaking).

- Check the oil level in the reservoir. With the liftgate platform at the bottom of its travel, the fluid should be two-thirds full. BE SURE THE CYLINDER IS COMPLETELY COLLAPSED. Add Tommy Gate Winter Grade, ISO grade, 32 hydraulic, or Dexron III/Mercon ATF if needed.

- Check the inside of the box for excessive accumulation of dirt. Clean as necessary.

- Check the roller chains, platform drop chains, the platform, uprights, vertical sliders, plastic wear pads, and the sprockets for damage or excessive wear. Replace any damaged or worn parts.

NOTE: If no issues are found during the 120 day inspections, we recommend that the chains be replaced after 4 years or 10,000 cycles whichever comes first. Chains should be replaced with original Tommy Gate roller chains only.

- Clean the inside surfaces of the uprights with a nonflammable solvent. Lubricate the roller chains, sliders, uprights, and pivot points with clean, high-quality, nondetergent, petroleum-based oil – DO NOT USE GREASE. Use nondetergent 10W @ (14°F-32°F), 20W @ (32°F-104°F), and 30W @ (104°F-122°F).

- Check the welds on the railgate, its mounting brackets and on the adjacent vehicle structure for cracks or damage. Repair any cracks or damage.

- Check the torque on all mounting bolts and re-tighten as necessary.

- Grease gas bottle rack fence pivot points if equipped.

For further information, feel free to contact Tommy Gate customer service by phone (1-800-LIFTGATE) or email, info@tommygate.com.

Tommy Gate is always working to design, build, and improve upon the finest liftgates in the world.

Accept no imitations.

Get in Touch

Have a question, or an idea for a future article on our blog?

We’d love to hear from you.